Our 7200 square foot facility, located in York Springs, Pennsylvania in the heart of 410 sprint car country. Once a customer’s engine arrives at our shop it goes through and initial check in where we discuss any changes the customer wants. Following that the engine goes to our tear down department, where it is disassembled, and initial inspections are done. Parts are stored per customer and ready for final cleaning.

Final cleaning is done in our washroom where we utilize Safety-Kleen parts washers which we recycle daily so there’s always clean fluid for washing our customers parts. Our spray cabinet is used for washing heads and blocks, and we have a large sonic cleaner which is used to clean injections, oil and water lines, nozzles, and many other parts of the engine.

In our cylinder head department, we have a Serdi seat and guide machine. We have a process where the cylinder heads are disassembled, parts cleaned, then the heads are soaked and cleaned so they are ready for final machining, which includes valve job and blending, surfacing, and last assembly.

Once the customer’s block has been thoroughly cleaned it is placed in line for cylinder honing in our Rottler H85AX CNC honing machine. Also in our machine shop area, crank shafts and rods are magnetic particle inspected for cracks, and rods reconditioned. For crankshafts we have a CWT Multi-Bal 5500 for balancing, and all crankshafts go through a polishing process before final cleaning.

Once all machine work is finished, the block goes through a final cleaning and is prepared for assembly. Here we go through a rigorous process of setting all of the final tolerances for the internal engine parts to ensure optimum performance and reliability.

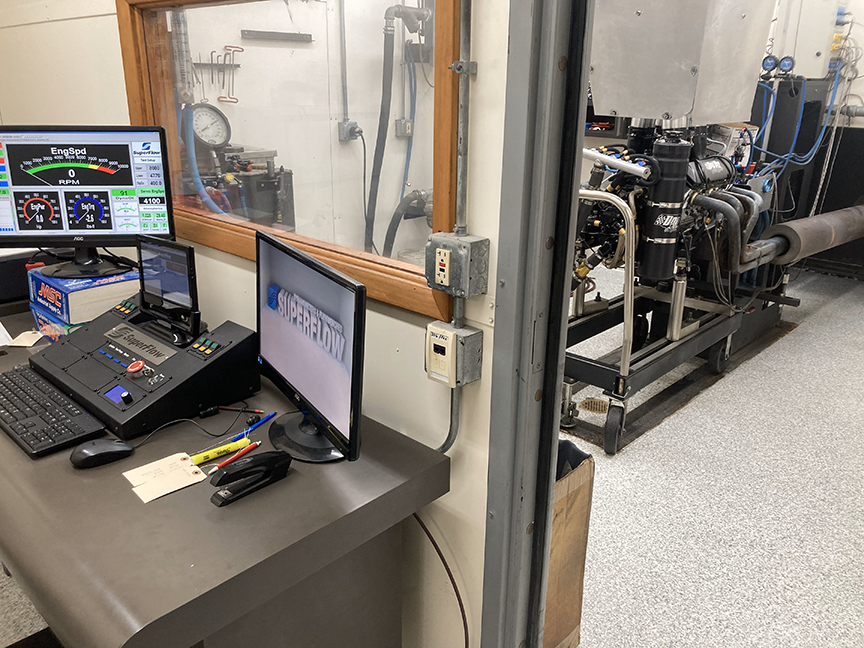

After the engine is through assembly it is ready for final testing and to be ran on our dyno. Prior to dyno testing we flow test our customers fuel pump to verify optimum performance. Once that has passed quality control, the engine goes to our dyno cell where it is broken in and tuned for optimum performance on our Superflow Powermark dynamometer.